Discover Reliable SMT Spare Parts and Machines for Your Projects

- 44791369

- Oct 6, 2025

- 3 min read

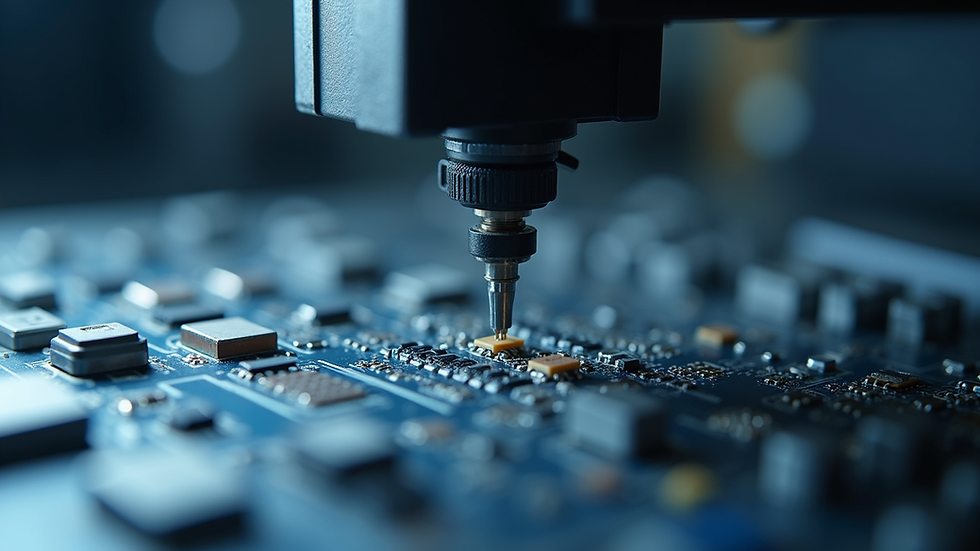

When working on surface-mount technology (SMT) projects, having access to reliable SMT spare parts and machines is essential. These components ensure your production line runs smoothly, minimizing downtime and maintaining product quality. Whether you are upgrading your equipment or replacing worn-out parts, understanding where to find trustworthy sources and what to look for can save you time and money.

Why Quality SMT Spare Parts Matter

Using high-quality SMT spare parts is crucial for maintaining the efficiency and accuracy of your assembly line. Poor-quality parts can lead to frequent breakdowns, misalignment of components, and ultimately, defective products. For example, a faulty nozzle in a pick-and-place machine can cause incorrect placement of components, leading to costly rework.

Key benefits of quality SMT spare parts include:

Increased machine uptime: Reliable parts reduce the frequency of repairs.

Improved product quality: Precise components ensure accurate assembly.

Cost savings: Avoid expensive downtime and rework.

Extended machine lifespan: Proper parts reduce wear and tear.

When sourcing parts, always check for compatibility with your specific machine model. OEM (Original Equipment Manufacturer) parts are often recommended, but high-quality aftermarket parts can also be a good option if they meet industry standards.

How to Choose the Right SMT Spare Parts

Selecting the right spare parts involves more than just matching part numbers. Here are some practical tips to help you make the best choice:

Identify the exact part needed: Consult your machine’s manual or manufacturer’s website for part specifications.

Check part compatibility: Ensure the part fits your machine model and version.

Evaluate supplier reputation: Choose suppliers with positive reviews and proven reliability.

Consider part quality: Look for certifications or quality assurance guarantees.

Compare prices: While cost is important, avoid cheap parts that compromise quality.

Ask about warranty and support: Reliable suppliers offer warranties and technical assistance.

For example, if you need a replacement conveyor belt for your SMT line, verify the belt’s material, length, and width to match your machine’s requirements. Also, inquire if the supplier provides installation guidance or after-sales support.

One trusted source for SMT spare parts and machines is qysmt-spare&machine, which offers a wide range of components with quality assurance.

What is the top 10 popular SMT machine brand?

Knowing the leading SMT machine brands can help you find compatible spare parts and reliable machines for your projects. Here are ten popular SMT machine brands widely recognized in the electronics manufacturing industry:

ASM Assembly Systems - Known for high-speed placement machines.

JUKI - Offers versatile and reliable pick-and-place machines.

Panasonic - Provides advanced SMT solutions with excellent precision.

Fuji - Renowned for innovative and efficient SMT equipment.

Yamaha - Delivers flexible and user-friendly machines.

Mycronic - Specializes in high-accuracy placement systems.

Samsung - Offers cost-effective and reliable SMT machines.

Hanwha - Known for automation and smart factory integration.

DEK - Focuses on printing and inspection equipment.

10. Europlacer - Provides modular and scalable SMT solutions.

When sourcing spare parts, it is important to know the brand and model of your machine to ensure compatibility. Many suppliers, including qysmt-spare&machine, stock parts for these top brands.

Tips for Maintaining Your SMT Machines

Proper maintenance of SMT machines extends their lifespan and keeps production running efficiently. Here are some actionable recommendations:

Regular cleaning: Dust and debris can affect machine accuracy. Clean nozzles, feeders, and conveyors frequently.

Scheduled inspections: Check for worn or damaged parts and replace them promptly.

Lubrication: Apply lubricants to moving parts as recommended by the manufacturer.

Software updates: Keep machine software up to date to improve performance and fix bugs.

Operator training: Ensure staff are trained to handle machines correctly and spot issues early.

By following these tips, you reduce the risk of unexpected breakdowns and maintain consistent product quality.

Where to Find Reliable SMT Spare Parts and Machines

Finding a trustworthy supplier is key to sourcing quality SMT spare parts and machines. Here are some factors to consider when choosing a supplier:

Product range: Look for suppliers offering a wide variety of parts and machines.

Quality assurance: Verify if the supplier provides certified or OEM parts.

Customer support: Good suppliers offer technical assistance and after-sales service.

Delivery options: Fast and reliable shipping minimizes downtime.

Pricing: Competitive pricing with transparent policies.

One reputable supplier is qysmt-spare&machine, which provides a comprehensive selection of SMT spare parts and machines. Their website features detailed product descriptions and customer support to help you find exactly what you need.

Enhancing Your SMT Projects with the Right Equipment

Investing in reliable SMT spare parts and machines is an investment in your project’s success. High-quality components ensure your production line operates smoothly, reduces errors, and improves overall efficiency. Whether you are a small workshop or a large manufacturing facility, sourcing parts from trusted suppliers like qysmt-spare&machine can make a significant difference.

By understanding the importance of quality parts, knowing the top machine brands, and following maintenance best practices, you can optimize your SMT projects for better results and long-term reliability.